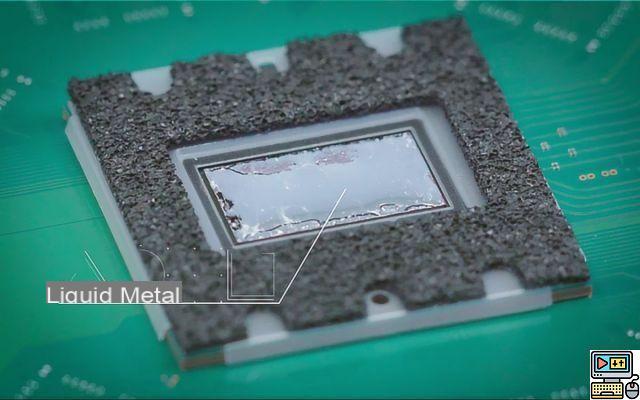

Sony revealed during a teardown of the PS5 that the console used liquid metal instead of thermal paste on the console chip. A choice that allows a better interface between the chip and the cooling solution to significantly increase its efficiency. Even if it was not as simple to implement as it looks.

The info was discovered during the first disassembly video of the PS5. Sony's new console no longer uses thermal paste to interface its SoC with heat pipes and other radiators, but liquid metal. As you know processors give off a lot of heat, and as the power of consoles increases, the issue of heat dissipation becomes central. Engineers have several options for this: fans, copper masses, heat pipes and other very thermally conductive materials, radiators, vapor chamber... However, to get the most out of a heat dissipation solution, the question arises ofinterface between components, especially between the SoC and the cooling solution.

As a general rule, both PCs and consoles use a type of material that is as well known as it is mastered: thermal pastes. This is a somewhat thick paste that must be applied to the die in a certain amount. Thermal pastes usually have some very desirable common characteristics: they do not leak, do not conduct electricity, and they do not attack surrounding materials. While being rather efficient at conducting thermal energy. Gold for some years now, overclocking enthusiasts have often opted for another type of thermal paste: liquid metal alloys.

Also read: PS5- the first tests reveal a very quiet console, unlike the PS4

PS5: liquid metal allows Sony to get the most out of its cooling solution

This type of interface transmits heat better, because not only do these alloys better fit the surfaces to be interfaced, but they also have a better thermal gradient which allows the whole to gain significantly in efficiency. In applications where the number of constraints weighing on heat dissipation is high, playing with thermal paste makes it possible to push conventional cooling solutions to their limits – and thus avoid opting for much more expensive solutions, such as for example a steam room like on Xbox One X.

Sony engineer Yasuhiro Ootori explained: “the PS5 SoC is a very small die clocked at a very high frequency. This leads to a very high thermal density in the silicon die, which required to significantly increase the performance of the thermal conductor otherwise known by the acronym TIM, between the SoC and the heat sink.“. And to add:PS5 uses liquid metal to ensure high, stable, and long-lasting cooling performance“. Of course, this is not Sony's only trick to ensure optimal cooling. The firm has for example opted for a larger format which leaves more room for a more imposing dissipation solution.

But adding to that liquid metal in the PS5, Sony was able to do without a steam chamber which could have increased the price of the console, without ensuring such optimal dissipation. Still, Sony's choice is far from trivial and posed some challenges that the manufacturer had to solve. First, unlike thermal paste which is, as its name suggests, a solid paste, liquid metal is… liquid.

Liquid metal in the PS5 poses an industrial challenge

It is therefore necessary to put very little to “wet” the component without excess. But that's not all because this amalgam has another defect: it conducts electricity. If this is not really a problem for amateurs who replace the thermal paste of their machine by liquid metal themselves, it is more difficult to integrate this material into industrial production processes.

At the risk of drastically lowering the production yield and increasing the rate of breakdowns. And that's not all : liquid metal has a destructive effect on some metals. It can in fact slip into the metal structure, reducing the mechanical properties of the assembly to nothing. We therefore understand the Sony engineer when the latter launches: “Adopting this liquid metal cooling mechanism took us two years. This allowed us to conduct many tests“. In fact, by bringing the PS5 to market, Sony is the first firm to launch a consumer product containing liquid metal.

What may help the firm to win the console war, at least in the field of innovation. Other manufacturers should soon follow suit. Asus has notably revealed that ROG PCs containing liquid metal will be marketed by the end of the year.